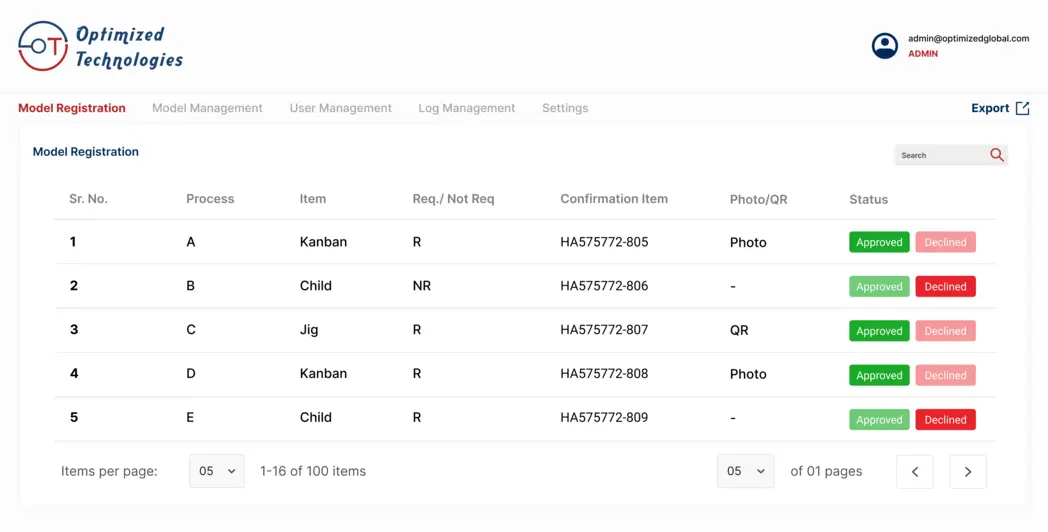

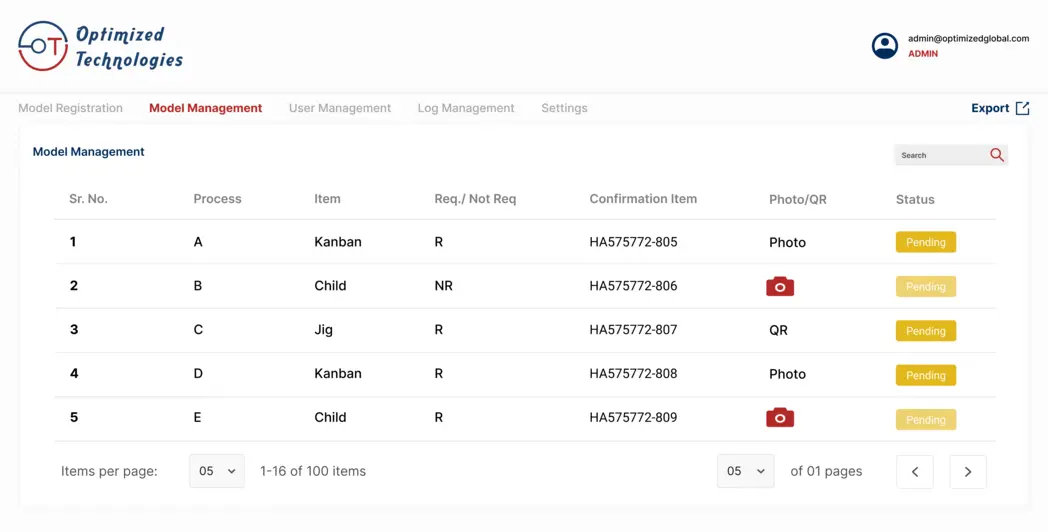

Interface

Client Background

The client owns an Automobile manufacturing facility. The client’s customers include Tata and Toyota among others.

OTI Relationship with Client

This whole task requires continuous manual monitoring at the location which makes the whole process very tedious.

Challenges

The machines and the spare parts need continuous monitoring and previously the software that client was using was not an effective one.

Therefore, this whole system needs to be modified to smoothen the whole process of manufacturing where analytics, centralized database, and alert system are developed into the software in order to get notified about the critical aspects in the facility.

Email, message, and notification:

- Notification to operator and engineer/manager after completion of upgradation of change over sheet with model number and quantity.

- Generate notifications if input/scanned data doesn’t match with the database values.

- Sheet assigning, sheet completion.

Solution

Centralized database and dashboard for data logging and data monitoring for a change-over sheet of machines

Centralized database:

- Data history maintenance for tracking changes over time.

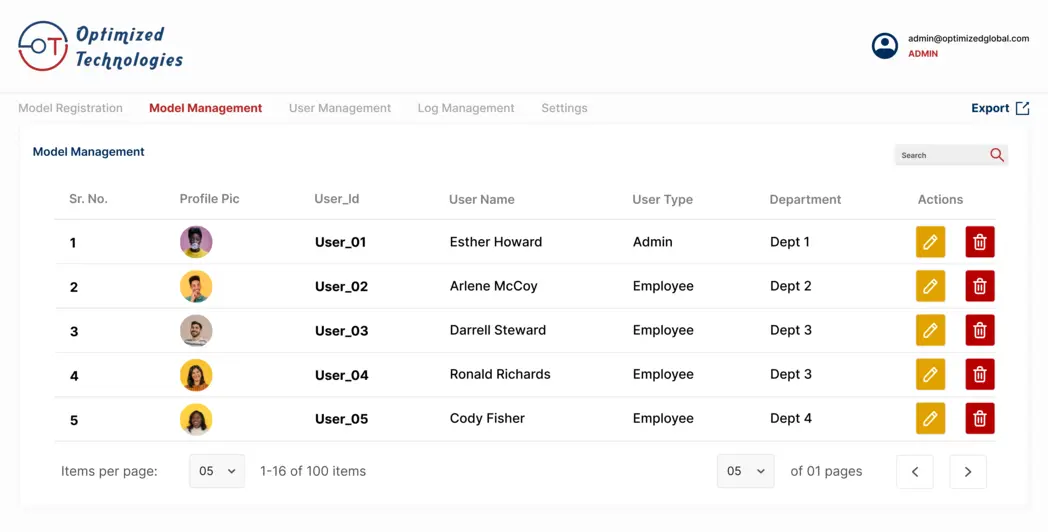

- User authentication with login credentials.

- Granular permissions based on hierarchy for data access.

- Centralized storage of multimedia content for various machines and programs.

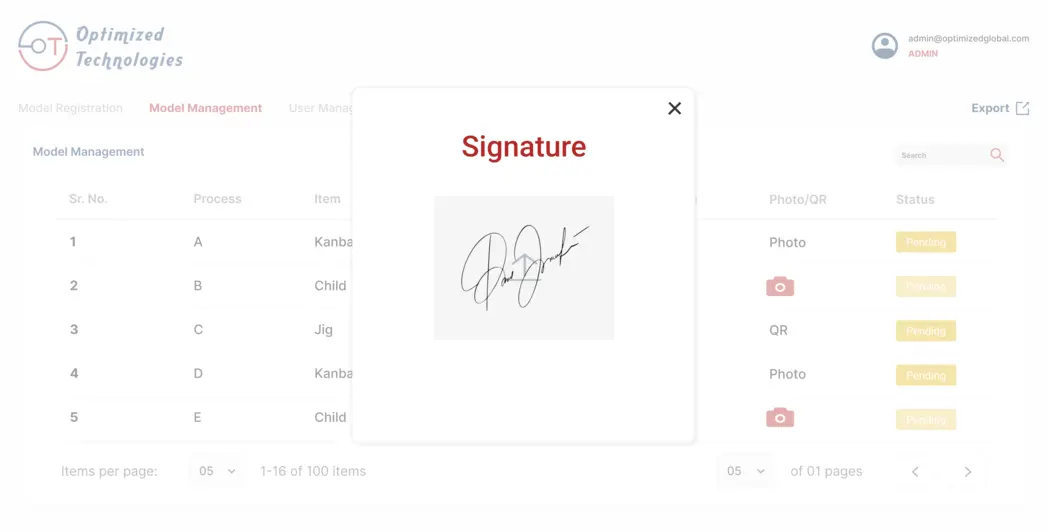

- Automated notifications and document uploads in PDF or Excel formats, with digital signature support.

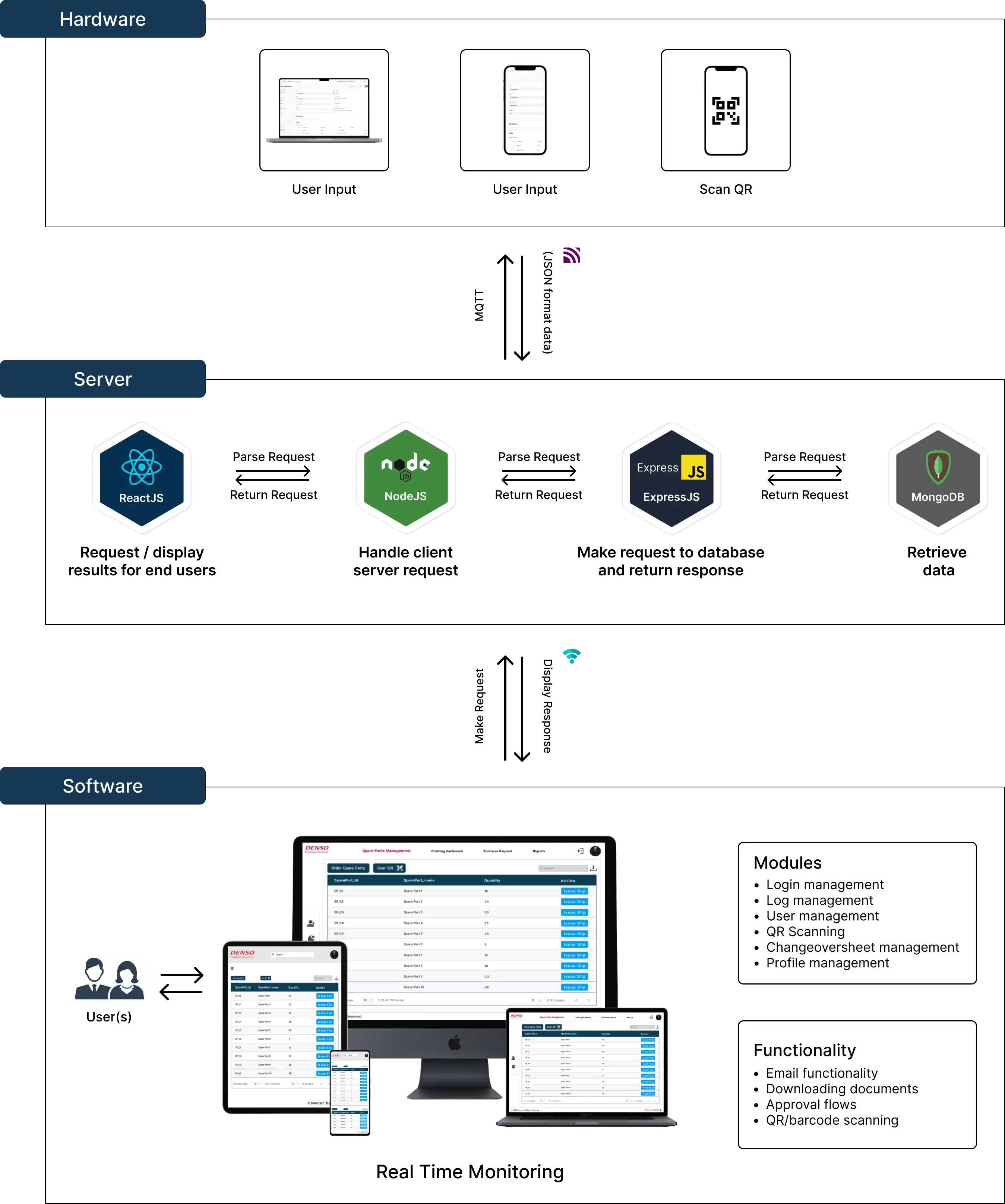

Architecture

Case Study

Let us create an IoT strategy, implementation and evolve your IoT solution.

Technologies We Work With

Value Proposition

Optimized Technologies Inc. has provided a system with the help of customized cloud, and Mobile application software that can handle and validate the functionalities of change-over data logging on a digital dashboard.

By transforming the whole process digitally, the entire functionality of change over data logging has been simplified hence allowing the users to effectively monitor and analyze the whole process.

Why Optimized Technologies Inc.?

Optimized Technologies Inc. is a trusted IoT and Generative AI solutions provider, delivering secure, scalable, and end-to-end services for enterprises. Our deep expertise in device connectivity, data integration, and AI application design enables organizations to unlock actionable insights and automation. We build solutions with enterprise-grade security and cloud-ready scalability, ensuring performance and compliance at every stage. From consultation to deployment and continuous optimization, we provide complete lifecycle support tailored to business needs. With a proven track record across industries, we empower businesses to achieve digital transformation, enhance efficiency, and stay competitive in the era of AI and IoT.